Bocce Builders of America offers services in all aspects of the bocce court construction and the surfacing process. Our crews have years of experience and travel the world assisting and supervising the correct installation of bocce courts. Because of location logistics, it is often better for us to design your court from our home office and only visit the site if necessary to confirm construction details. We can work with your crews or send our own. Once the court borders and base are installed, we ship our proprietary surface systems to the project and can also provide a warranty supervisor for out of area projects to complete the final surface installation with the help of your on site labor. The Pacific Pearl surface system can be installed in as little as 1-2 days while the Official Pro Synthetic surface installation takes closer to a week or longer. The Fog City Blend can be installed by your local crew. Whatever the situation, Bocce Builders is here to make your bocce dreams a reality!

The following pages will detail the construction process for each system.

Pacific Pearl Construction System

The Pacific Pearl Old World bocce ball construction system is a hybrid of organic and synthetic materials and uses natural elements from the earth as well as a fibered synthetic base medium to lock in the cushioned infill layers. First, we excavate to a proper depth - about 13” down is best (or a combination of grading down and raising the sidewalls will also work). Next, with our full construction model and depending on the size of the court, we trench a drainage line for our perforated French drain system and will stub that at the end of the court (others will take that water to a central drain or install some type of drywell so the water can dissipate on its own). Since the bocce court needs to be level, it's critical that we get the water permeating through the surface at a reasonable rate. Without the drainage, water would continue to build up in the court play area and the cushioned sands and oyster blend with fine particles might tend to compact over time which could restrict proper drainage of the court. The great news with our latest technology Pacific Pearl Bocce Surface is you don’t have to worry about divots, dents, roll marks or the accumulation of other organic materials such as leaves, grasses, animal matter or other bad stuff. You simply blow the surface clean since these other materials can't work their way into the Pacific Pearl Bocce Surface like they would with traditional oyster shell, clay or decomposed granite courts from the past. Since our finished surface is only 1-1/8"” thick and lays over 2 other layers of engineered and compacted materials (about 5” of them), the finished playing surface is resilient, has a role speed of about 10 (as tested on our stimpmeter) and very easy to keep looking good and playing great!

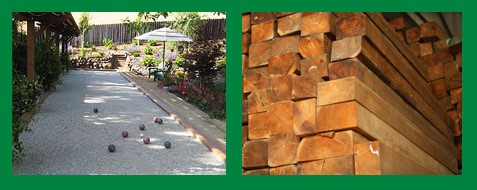

After the drains are installed, we typically form and pour the perimeter border at the correct finished elevation allowing for the remainder of the drain system, base and finished surface. Usually we end up with a 12”-14” perimeter wall height. After the forms are stripped, we start the installation of the drain tile, fabric, base and proprietary Pacific Pearl bocce blend system. Also during this time, all the 2" x 6" hand selected vertical grain, clear, kiln dried cedar bocce boards are mounted to the concrete surface at the correct height allowing for the various layers of material to be placed. Once the final Pacific Pearl Bocce Surface is installed with its mid cushion layer and final oyster blend, it's bocce time!

The surface specifications for your new court will generally stay the same regardless of alternative borders. A couple of alternatives for installing the border is to use 6" x 8" cedar timbers or 2" x 12" planks mounted to 4" x 4" posts (be careful as there are lots of problems with the plank border installations). If you can afford to have the concrete walls and mounted cedar boards, that's the best. Second best is a full 8" x 12" cedar beam secured with rebar every 3'-5'.

Official World Synthetic Construction System

Bocce Builders of America specializes in performance based, maintenance free bocce surface systems. A few of the most significant advances in bocce surfaces has come in the synthetic fiber and polyurethane—EPDM based systems. Our patent pending World Synthetic Surface System is second to none when it comes to correct ball roll, desired speed, consistency, performance and ease of maintenance. At the higher levels of bocce play, ball speed is typically faster and resistance free ball roll is desired. Typically, this surface requires a court to be at least 10' x 60' and larger is recommended. For somewhat slower ball roll speeds and shorter courts, we generally recommend the Pacific Pearl Bocce Surface System as the better performance alternative.

The correct installation of our Official World Synthetic Bocce System would include the following:

- Correct grading and leveling of site

- Forming of concrete borders or the placement of timbers

- Installation of a vapor barrier

- Placing and tying of structural rebar

- Installation of alternative drain systems

- Pouring walls and bocce court base

- Installation of Official Synthetic Bocce Surface System

- Installation of Side Walls

- Play Bocce!

See Specification links for more details of installation process*

*please note, only trained and certifide Bocce Builders of America installers are authorized to install this surface.

Initial Site Considerations

Construction Process

Location, Location—First, find a place for your new bocce court, which is located near the main part of your yard and reasonably close to the home. Friends and family like to be near food, bathroom facilities and mingle with others who might not be participating. In some instances, the court could be set out near a vineyard or other area, but for most of us, build it to be seen or only camouflage it with beautiful trellises, wandering roses or stunning arbors. If the installation is in a commercial setting its best to install your court in a very central area. Bocce attracts great people and makes for a wonderful team bonding experience.

Access—How is all the equipment going to get to the site? A bobcat or small tractor might need to go over existing landscaping. Try to visualize the path of entry and exit. Do you need to lay plywood down on an extended area? (That cost can add up, too). Will the tractor be driving over a lawn? Is there a fence or tree in the way? How about a swimming pool or flower bed—probably don't want to go over those either. Plan ahead and then find the best course to follow.

You might end up digging by hand and wheel-barrowing things in and out. Doing everything by hand can get costly, so keep the access in mind. Often there are few choices and location trumps access, so go with location first and access next. If you have options, make them both work to your benefit.

There is also the issue of access for concrete. Can a truck access the bocce ball court site or will you need a pump. Either way will work. For most projects, a concrete pump will be required and will save your existing landscaping from getting squashed.

Site Considerations and Prep #2

Soil Density—It sounds crazy but whether you're working with sand or boulders it will make a significant difference in the cost of the site preparation. Make sure you understand your soil type. We have seen families use dynamite to help blow up big boulders. It's pretty exciting, but very expensive. Normally, most sites can be graded with a small bobcat and possibly a jackhammer attachment. That's the beauty of a bobcat—there are so many attachments that can make the job go easier.

Soil Percolation—This has to do more with the drainage, but is good to know. Is your soil sandy, clay, adobe, rocky or granite (ouch!—I hope it's not granite). Of course sand percolates the best, but sandstone doesn't percolate much at all and is brutal to dig. Adobe soils expand and contract more, but usually absorb water well where clay soils can be much denser and compact very tight.

Lawn and Irrigation—If your new bocce court is going where a lawn or other shrubbery is currently, then you need to plan on having the sod removed, hauled away and the sprinkler system capped or relocated. Bocce Builders can help you in this process to determine who would be best to modify the old systems. Often, we can coordinate and perform the required work to be done.

Site Considerations and Prep #3

Trees—Remember, most trees have roots that spread out and you can't dig too close to them or they'll die. Consulting with an Arborist is smart. The most strict guideline is to stay off trees to the extent of the drip line (how far out the branches extend). Since that's usually difficult, we generally need to stay at least 3' or more of the base of the tree depending on the size of the root structure.

Bocce Builders construction teams are trained in all of the areas critical to the construction of your new court and travel across the country supervising installations and installing surfaces.

Grading and Site Preparation

Site Clearing, excavations and leveling. The site has to be graded correctly paying attention to access, existing hard and soft scape. Most sites will be graded completely level, sub base compacted correclty and organic material removed. Existing concrete might have to be removed or in some cases, can be used as the bocce court base. Paying attention to access, existing landscapes and distance for offhaul will be important in this phase of the construction process.

Bocce Side Walls

This section contains information regarding the installation of the classic concrete and replaceable timber border systems designed and installed for bocce ball courts by Bocce Builders of America. Additional bocce ball construction techniques involve the installation of a timber only border using 6” x 8” weather treated cedar beams.

Forming

A picture is worth a thousand words. We form the perimeter of the bocce court (in the left situation below, there are actually 2 courts side by side) using 2" x 12" or 2" x 6". Normally it's best to use 2" x 6" so you can tie them together prior to pouring. These ties keep the forms from expanding out with the pressure of the concrete. If we use 2" x 12" boards, they must be staked and kicked more often.

Steel

The next process involves laying and tying steel rebar in the perimeter border foundation. As you can see, we also hang the steel so it stays more to the center of the concrete and doesn't fall to the ground. Bocce Builders uses both #3 and #4 rebar in the foundation wall.

The Pour

Concrete is ordered and as you can see, a pump is usually required. We use a special 6 sack mix to provide a higher psi and add color to the mix. The concrete is usually vibrated in place to minimize any concrete voids. After the concrete sets up a bit, we remove the top bracing and trowel the top face and edges. Typically, the edges are rounded but can be angled as well.

Timber Borders & Installation

Attached to Concrete:

After the concrete forms have been stripped and most of the base layers installed, we attach the perimeter boards by using concrete anchor bolts. This allows us to change the boards years later when necessary to keep the court looking great. If you install a beam or post and plank system, it would be a much more difficult process to change these out down the road. We typically use a very high end clear, vertical grained, kiln dried cedar board which is treated with an eco-friendly weather proofing but also have options to use more exotic woods like Zebrawood, Philippine mahogany or other interesting woods proven to resist the effects of weather and decay.

Freestanding:

There are a number of ways to install a timber border without using concrete. First and best is to use a full 8" x 12" cedar beam, drill 1/2" holes every 3'-5' and then hammer a 4' piece of 1/2" rebar flush to the top of beam. Other cheaper and not so groovy ways to do this is by stacking 2- 6” x 8” treated timbers or if you really want to go cheap just use one. Of course you will also secure these with rebar as described above. Finally, if you really broke but must have a court, you can also use the old fashion 4" x 4" post and pressure treated 2" x 12" planking system. Generally, we do not recommend the installation of 4” x 4” posts and planking. Over a short period of time, the wood tends to warp and fall apart….cheaper is not always your friend!